Dairy powders are dairy products that have been dried or evaporated. Dairy powders have a much longer shelf life than liquid dairy products and do not need to be refrigerated due to their low moisture content. Another goal is to reduce volume for easier transit and storage. powder processing equipment help to dehydrate the milk retaining its properties.

Milk is a food that everyone requires. It is one of the most nutritious drinks, abundant in protein, calcium, vitamin B12, and riboflavin. As stringent lockdowns are implemented, it is impossible to maintain a fresh supply of milk. Preservation is necessary in these times. Powdered milk, like raw milk, contains a lot of nutrients. It is very beneficial as it has minerals and vitamins. Dry, powdered milk can save you a lot of money while also being more convenient to use and store. Milk can be preserved in this manner.

Dairy-based milk powders provide shelf-stable, nutritious alternatives to fresh milk as a healthy, fast drink or as ingredients in various recipes. Consumers want products that are highly soluble, consistent, and dissolve rapidly. Manufacturers demand dependable sanitary equipment and plants that produce high-quality milk powders with the required chemical composition and physical properties.

History:

Marco Polo recorded in the 13th century that Kublai Khan’s soldiers carried sun-dried milk on their excursions. Milk has recently been dried in thin layers on heated rollers. The first patents for this process were issued around the turn of the century. Until the 1960s, when spray drying became popular, roller drying was the primary method of manufacturing milk powders. Milk powder production is a massive business in the twenty-first century. Milk powder production is a straightforward operation that may be done considerably. Production entails gently removing water at the lowest possible cost while adhering to strict sanitary standards.

Process of powdering:

- Evaporation is an essential process in producing milk powder because it removes most of the surplus water from the liquid mix before spray drying.

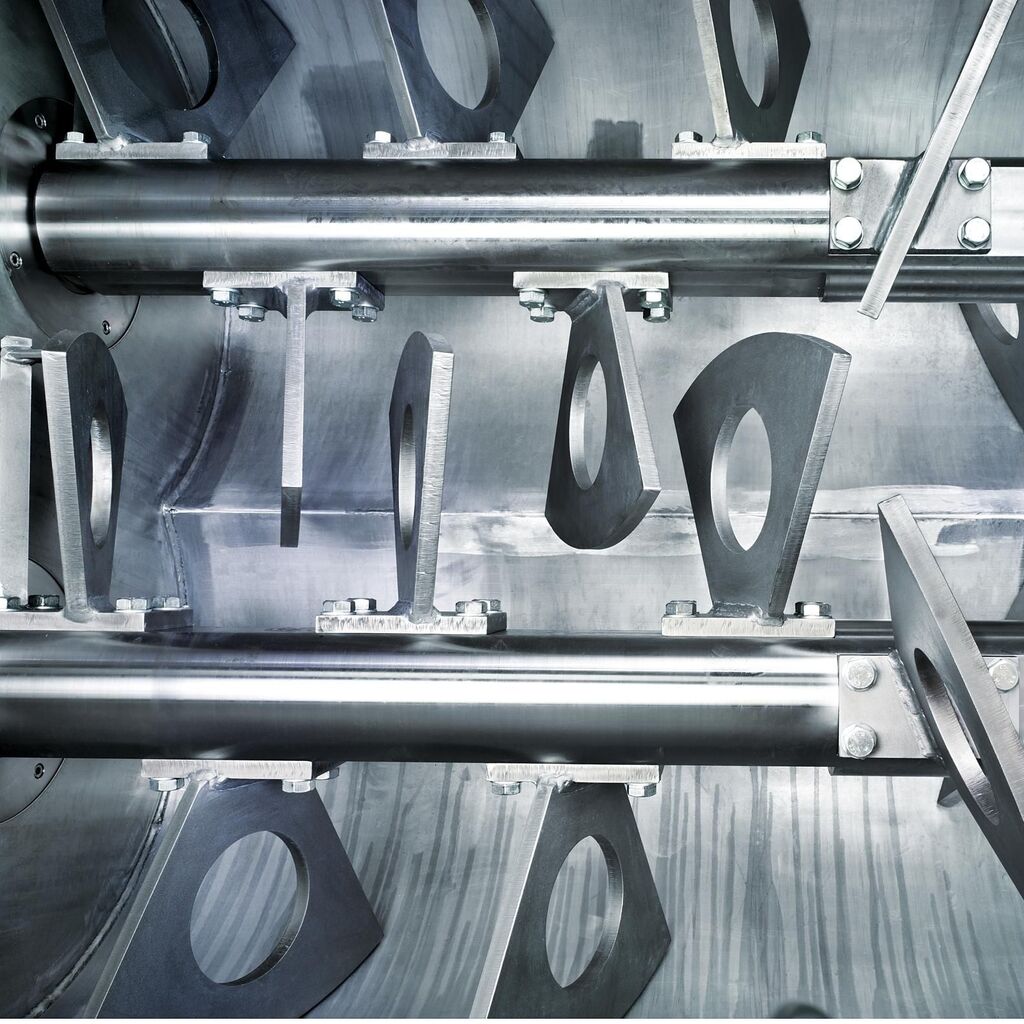

- During the spray drying stage, the physical qualities of the final milk powder product are specified. This critical process influences particle size and aggregation, powder density, solubility, and stability. We designed spray drying technologies to generate uniform, precisely defined powders in every batch.

- All stages of powder handling require hygienic, safe, and precise technologies. GEA technologies reduce the danger of contamination, ensuring that your environment is safe.

- Multiple phases in milk powder production rely on careful temperature control of heating and refrigeration.